LDL-1 vs. LDL-2: Streamline Your Maintenance with the Right Solution

LDL-1 vs. LDL-2: Streamline Your Maintenance with the Right Solution

When it comes to industrial maintenance, the right lubricant or multi-purpose spray can dramatically impact both performance and productivity. Whether you're an MRO professional, facility manager, or operations technician, the tools and chemicals you rely on must perform under pressure and deliver consistent results.

At Tripakus.com, we specialize in solutions that make maintenance more effective and efficient. Our two flagship maintenance products—LDL-1 and LDL-2—are engineered to meet different yet essential needs. While both products deliver excellent protection and reliability, they are designed with distinct purposes in mind.

In this detailed comparison, we’ll break down the specific features, applications, and benefits of LDL-1 and LDL-2, helping you make an informed decision that supports the longevity of your equipment and the efficiency of your maintenance processes.

Understanding LDL-1: The All-Purpose Maintenance Powerhouse

LDL-1 is an advanced maintenance spray designed for maximum versatility across a wide range of environments. It is formulated to combine electrical insulation, moisture displacement, rust and corrosion removal, and general lubrication into one easy-to-use solution.

Key Features of LDL-1

-

Electrical Insulation: One of the most notable advantages of LDL-1 is its ability to protect electrical systems. It forms a non-conductive barrier that safeguards sensitive components, even in damp or moisture-prone environments.

-

Moisture Displacement: LDL-1 is highly effective in displacing water and other moisture, making it suitable for outdoor, marine, or humid environments where electrical failures can occur due to condensation or exposure.

-

Rust and Corrosion Removal: Thanks to its penetrating formula, LDL-1 can loosen rusted bolts, free corroded parts, and clean oxidation from metal surfaces, effectively rejuvenating older or poorly maintained equipment.

-

Lubrication: LDL-1 provides reliable lubrication for moving parts, reducing wear and friction in standard mechanical assemblies.

-

Product Consolidation: Because it serves multiple purposes, LDL-1 allows you to replace several single-function products in your toolkit, cutting down costs and simplifying inventory management.

Best Use Cases for LDL-1

-

Maintenance tasks involving electrical panels, switches, relays, and terminals.

-

General-purpose lubrication for hinges, locks, valves, and joints.

-

Emergency repairs in field operations or mobile units.

-

Rust removal and prevention in humid or coastal areas.

-

Facilities seeking to streamline inventory and reduce SKUs.

Exploring LDL-2: Heavy-Duty Lubrication for High-Stress Applications

LDL-2 is a high-performance lubricant developed for industrial applications that demand exceptional wear protection and friction reduction. It is specifically designed to function under intense pressure, high temperatures, and continuous mechanical stress.

Key Features of LDL-2

-

Superior Friction Reduction: LDL-2 contains advanced additives that reduce friction between surfaces, even in the most demanding environments. This is critical for extending the operational life of machinery components.

-

High Heat Resistance: Where standard lubricants break down under temperature extremes, LDL-2 remains stable. It performs reliably in high-RPM or high-load environments where thermal stress is a concern.

-

Wear and Tear Minimization: LDL-2 excels in minimizing component wear, helping businesses reduce equipment downtime, avoid premature part replacements, and increase overall productivity.

-

Precision Application: Though it is not a multipurpose product like LDL-1, LDL-2 delivers superior results when used in the specific scenarios it was designed for.

Best Use Cases for LDL-2

-

Manufacturing environments with heavy machinery and high operating loads.

-

Mining, construction, and agricultural equipment exposed to extreme conditions.

-

Gearboxes, bearings, chains, and rotating assemblies under constant pressure.

-

Preventive maintenance programs focused on long-term asset protection.

-

Companies seeking to reduce machine failure rates and extend maintenance intervals.

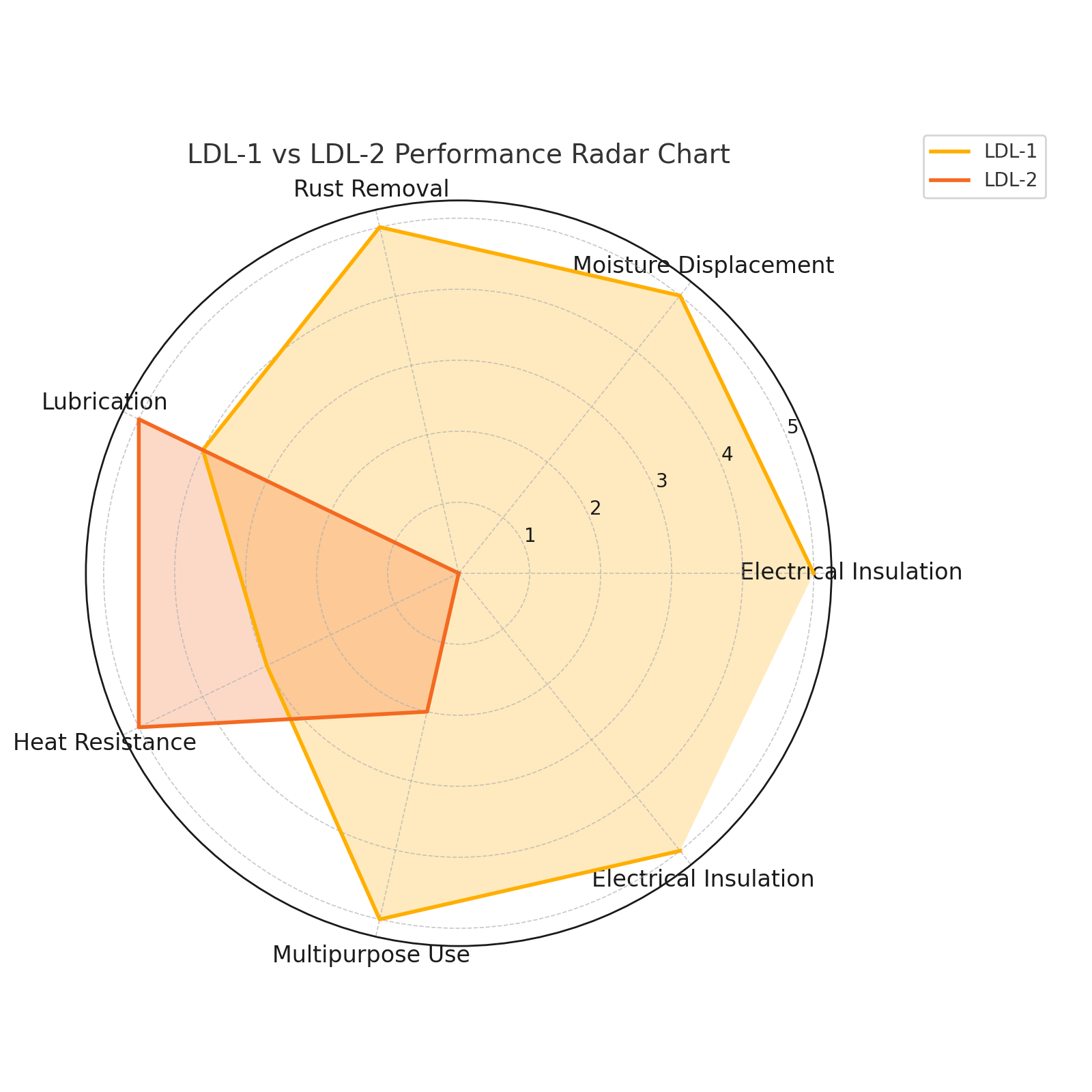

Side-by-Side Comparison: LDL-1 vs. LDL-2

To help you quickly assess the differences, here is a comprehensive comparison of the two products:

| Feature | LDL-1 | LDL-2 |

|---|---|---|

| Primary Focus | All-purpose protection and versatility | Heavy-duty lubrication and maximum wear protection |

| Key Benefit | Multi-functional; replaces multiple maintenance tools | Extreme friction reduction and durability under stress |

| Best For | Electrical systems, rust removal, general maintenance | Industrial equipment, high-friction applications |

| Electrical Insulation | Yes | No |

| Moisture Displacement | Excellent | Not applicable |

| Rust & Corrosion Removal | Powerful penetration and removal | Not designed for rust treatment |

| Lubrication | Good, general-purpose lubrication | Superior, specialized lubrication |

| High Heat Resistance | Moderate | Excellent |

| Multipurpose Functionality | Outstanding | Limited to specific applications |

| Application Environment | Flexible across multiple settings | Requires targeted, high-performance environments |

Which Product Should You Choose?

Choosing between LDL-1 and LDL-2 ultimately depends on your specific needs.

Choose LDL-1 if:

-

You want to consolidate multiple maintenance products into a single, all-in-one solution.

-

Your tasks involve electrical systems and require moisture protection.

-

You manage facilities or vehicles where general-purpose protection and quick repairs are a priority.

-

You're looking for a cost-effective way to handle diverse maintenance challenges.

Choose LDL-2 if:

-

You operate high-value industrial equipment and require precision lubrication to maintain uptime.

-

Your machinery runs under heavy load or high-speed conditions, and you need a lubricant that won’t break down under pressure.

-

Your priority is extending equipment life, reducing mechanical failure, and enhancing operational safety.

-

You already use specialized maintenance plans and need a product that aligns with high-performance standards.

Final Thoughts: Streamline Maintenance, Maximize Uptime

At Tripakus.com, we understand the real-world pressures maintenance professionals face every day. That’s why we provide products like LDL-1 and LDL-2—not just for performance, but for peace of mind.

-

LDL-1 empowers you with all-in-one versatility, reducing the need for multiple products and simplifying daily maintenance tasks.

-

LDL-2 gives you industrial-strength lubrication where failure is not an option, ensuring equipment runs smoother and lasts longer.

Still not sure which solution is right for your operation? Our team is ready to help. Contact us today for tailored advice, or shop our full line of maintenance products and experience the Tripakus difference.